Welcome to the world of small manufacturing businesses, where innovation and efficiency are key to success. In today’s fast-paced market, it is essential for small manufacturers to optimize their operations in order to stay competitive. One way to achieve this is through the implementation of ERP (Enterprise Resource Planning) systems. These powerful software solutions can streamline processes, improve communication, and ultimately boost productivity. Let’s explore how ERP systems can help small manufacturers thrive in a highly competitive environment.

Overview of ERP Systems for Small Manufacturing

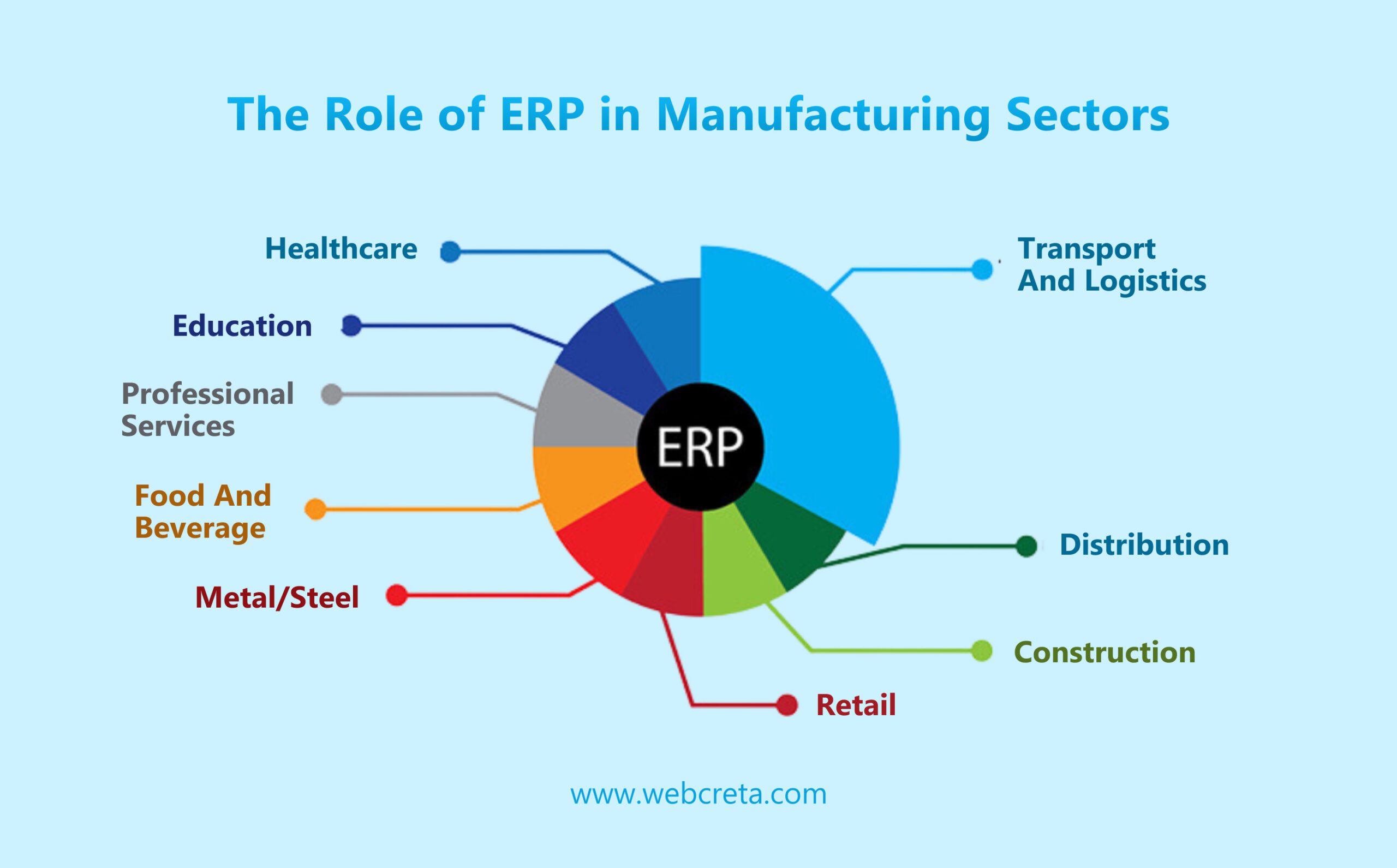

ERP stands for Enterprise Resource Planning, which is a software system that integrates various aspects of a business, such as inventory management, production planning, human resources, and financial management. In the manufacturing industry, ERP systems are essential for streamlining processes, increasing efficiency, and improving overall productivity. While ERP systems were traditionally used by large corporations, there are now options available specifically tailored for small manufacturing companies.

One of the main advantages of implementing an ERP system in a small manufacturing company is the ability to centralize all data and processes. This means that employees can access real-time information from anywhere, leading to better decision-making and faster response times. Additionally, by automating tasks such as order processing, inventory management, and scheduling, small manufacturers can reduce errors and save time and resources.

Another benefit of using an ERP system is the ability to track and analyze key performance indicators (KPIs) in real-time. This allows small manufacturing companies to identify trends, monitor production efficiency, and make informed decisions to improve overall performance. By having access to accurate data, business owners can better understand their operations and identify areas for improvement.

ERP systems for small manufacturing companies also offer scalability, allowing businesses to easily expand and grow while maintaining efficiency. As companies evolve and add new products or services, the ERP system can be customized to accommodate these changes. This flexibility ensures that the system remains relevant and effective for the long term.

Furthermore, ERP systems help small manufacturing companies comply with industry regulations and standards. By automating processes and ensuring data accuracy, businesses can easily generate reports and audits to demonstrate compliance. This not only reduces the risk of fines or penalties but also improves overall business reputation.

In conclusion, ERP systems are invaluable tools for small manufacturing companies looking to improve operations, increase efficiency, and drive growth. By centralizing data, automating processes, and analyzing KPIs, businesses can make better decisions, save time and resources, and stay competitive in a rapidly evolving industry.

Benefits of Implementing an ERP System in Small Manufacturing Companies

Implementing an ERP system in a small manufacturing company can provide a wide range of benefits that can help streamline operations, increase efficiency, and improve overall productivity. Here are some of the key advantages of incorporating an ERP system into your small manufacturing business:

1. Increased Efficiency: One of the most significant benefits of implementing an ERP system in a small manufacturing company is the increase in overall efficiency. By centralizing all the company’s data and processes into one integrated system, employees can easily access information and collaborate more effectively. This can help reduce errors, improve decision-making, and ultimately increase productivity.

2. Improved Inventory Management: With an ERP system in place, small manufacturing companies can better manage their inventory levels. The system can provide real-time updates on stock levels, track inventory movements, and automatically generate replenishment orders when stock runs low. This can help reduce the risk of stockouts, minimize excess inventory, and optimize inventory turnover.

3. Enhanced Customer Service: An ERP system can also play a crucial role in enhancing customer service for small manufacturing companies. By having access to real-time customer data, sales orders, and order statuses, employees can provide more accurate and timely information to customers. This can lead to improved customer satisfaction, reduced lead times, and increased customer loyalty.

4. Cost Savings: Implementing an ERP system can lead to cost savings for small manufacturing companies in various ways. By streamlining processes and reducing manual tasks, companies can save time and resources. The system can also help identify inefficiencies, eliminate redundancies, and optimize workflows, leading to cost reductions in the long run.

5. Better Decision-Making: An ERP system can provide small manufacturing companies with valuable insights and analytics that can aid in decision-making. By tracking key performance indicators, analyzing trends, and generating reports, managers can make informed decisions to drive the business forward. This data-driven approach can help identify opportunities for growth, spot areas for improvement, and make strategic decisions to stay competitive in the market.

In conclusion, implementing an ERP system in a small manufacturing company can bring about numerous benefits, including increased efficiency, improved inventory management, enhanced customer service, cost savings, and better decision-making capabilities. By investing in an ERP system, small manufacturing companies can effectively streamline their operations, boost productivity, and stay ahead of the competition in today’s fast-paced market.

Key Features to Consider When Choosing an ERP System for Small Manufacturing

Choosing the right ERP system for a small manufacturing business is crucial for streamlining processes, improving efficiency, and ultimately driving growth. There are several key features that small manufacturers should consider when evaluating ERP systems to ensure they are getting the best solution for their specific needs. Let’s take a closer look at some of these important features:

1. Scalability

One of the key features to consider when choosing an ERP system for small manufacturing is scalability. As your business grows, your ERP system should be able to grow with you. Look for a system that can easily accommodate an increase in users, transactions, and data volume without requiring a complete system overhaul. Scalability is crucial for future-proofing your investment and ensuring that your ERP system can continue to meet your needs as your business expands.

2. Customization Options

Another important feature to consider is the level of customization options that the ERP system offers. Small manufacturing businesses have unique processes and requirements, so it’s important to choose a system that can be tailored to meet your specific needs. Look for an ERP system that allows for easy customization of workflows, reports, and dashboards, so you can configure the system to work the way you do. Customization options will not only improve user adoption but also ensure that the system can support your business processes effectively.

3. Integration Capabilities

Integration capabilities are essential for small manufacturing businesses, as they often rely on a variety of other systems and technologies to manage different aspects of their operations. When choosing an ERP system, it’s important to consider how well it can integrate with your existing systems, such as CRM software, inventory management tools, and e-commerce platforms. Look for an ERP system that offers seamless integration with third-party applications through APIs or pre-built connectors. This will help you centralize your data and processes, eliminate duplicate data entry, and improve overall efficiency across your organization.

4. Mobile Accessibility

In today’s fast-paced business environment, having access to real-time data and insights on-the-go is essential for small manufacturers. Look for an ERP system that offers mobile accessibility, allowing employees to access important information and perform tasks from anywhere, at any time. Mobile capabilities will enable your team to stay connected, make informed decisions, and respond quickly to changing market conditions. Whether it’s checking inventory levels, approving purchase orders, or viewing production schedules, mobile accessibility can greatly enhance productivity and agility within your organization.

5. User-Friendly Interface

Lastly, consider the user-friendliness of the ERP system when making your decision. A user-friendly interface is crucial for ensuring that employees can easily navigate the system, input data accurately, and find the information they need quickly. Look for an ERP system that offers an intuitive design, simple navigation, and customizable dashboards to improve user adoption and overall satisfaction. A user-friendly interface will not only increase efficiency but also reduce training time and support costs for your small manufacturing business.

By considering these key features when choosing an ERP system for small manufacturing, you can select a solution that will support your business growth, improve operational efficiency, and drive success in the competitive manufacturing industry.

Case Studies of Small Manufacturing Businesses Successfully Implementing ERP Systems

Implementing an ERP system can be a game-changer for small manufacturing businesses, streamlining processes, increasing efficiency, and improving overall productivity. Below are some case studies of small manufacturing businesses that have successfully implemented ERP systems:

Case Study 1 – ABC Manufacturing: ABC Manufacturing, a small family-owned business, struggled with managing their inventory and production schedules. After implementing an ERP system specifically designed for small manufacturers, they saw a significant improvement in their inventory management and production efficiency. The system allowed them to track inventory levels in real-time, automate order processes, and optimize their production schedules. As a result, ABC Manufacturing was able to reduce lead times, minimize stockouts, and improve customer satisfaction.

Case Study 2 – XYZ Inc: XYZ Inc is a small manufacturing business that specializes in custom-made products. Prior to implementing an ERP system, they faced challenges with order processing, visibility into their supply chain, and managing production costs. By implementing an ERP system tailored to their needs, XYZ Inc was able to streamline their order processing, improve visibility into their supply chain, and better manage their production costs. The system also helped them track the profitability of each custom order, enabling them to make data-driven decisions to maximize their profits.

Case Study 3 – LMN Industries: LMN Industries, a small manufacturing business with multiple locations, struggled with communication and collaboration between their different facilities. After implementing an ERP system that integrated all their locations onto a single platform, they saw a significant improvement in communication, coordination, and overall efficiency. The system enabled them to standardize processes across all locations, share real-time data, and improve visibility into their operations. As a result, LMN Industries was able to reduce costs, eliminate duplication of efforts, and improve overall productivity.

Case Study 4 – PQR Co: PQR Co is a small manufacturing business that specializes in producing electronic components. Prior to implementing an ERP system, they faced challenges with managing their complex supply chain, tracking production costs, and meeting customer demand. By implementing an ERP system that was specifically tailored to their industry, PQR Co was able to automate their supply chain processes, track production costs in real-time, and improve their production forecasting. The system also helped them identify cost-saving opportunities, streamline their purchasing processes, and optimize their production schedules. As a result, PQR Co was able to reduce lead times, lower production costs, and increase their profitability.

Tips for a Smooth Transition to an ERP System in Small Manufacturing Companies

Implementing an ERP system in a small manufacturing company can be a game-changer. It can streamline operations, enhance productivity, and improve overall efficiency. However, transitioning to a new ERP system can also be a daunting task. Here are some tips to help you make a smooth transition:

1. Plan Ahead: Before implementing an ERP system, it’s crucial to have a solid plan in place. Define your goals, create a timeline, allocate resources, and communicate with all stakeholders. Planning ahead will ensure that the implementation process goes smoothly.

2. Choose the Right ERP System: Not all ERP systems are created equal. It’s essential to select a system that aligns with your company’s unique needs and requirements. Consider factors such as scalability, ease of use, customization options, and integration capabilities.

3. Train Your Employees: One of the key factors for a successful ERP implementation is proper training. Make sure that all employees who will be using the system are well-trained on how to use it effectively. Provide continuous support and education to ensure a smooth transition.

4. Start Small: A common mistake many small manufacturing companies make is trying to implement all modules of the ERP system at once. Instead, start small by focusing on one area or department. This will allow you to iron out any kinks before rolling out the system company-wide.

5. Seek Support from Experts: Transitioning to an ERP system can be complex, especially for small manufacturing companies with limited IT resources. Consider seeking support from ERP consultants or specialists who have experience in implementing systems for similar businesses. They can provide guidance, support, and expertise throughout the process.

6. Test and Evaluate: Before fully implementing the ERP system, conduct thorough testing to identify any issues or areas for improvement. Encourage feedback from users and stakeholders to ensure that the system meets the company’s needs. Continuously evaluate and refine the system to optimize its performance.

7. Communicate Effectively: Communication is key during the transition to an ERP system. Keep all stakeholders informed about the progress, changes, and benefits of the new system. Address any concerns or questions promptly to ensure a smooth transition for everyone involved.

By following these tips, small manufacturing companies can successfully transition to an ERP system and reap the benefits of improved efficiency, productivity, and competitiveness in the market.